How Do SMD Leds Work? How to Use It and What Distinguishes SMD from COB Led

Using through hole components can be tiring especially when components need repeated mounting/dismounting such as LEDs and capacitors. This is where surface mounted technology (SMT) comes in handy. A surface mounted device (SMD) can be easily secured on any PCB by the means of solder. This tech is becoming the industry standard and has largely replaced the through hole technology.

There is a variety of SMDs that are in prevalent use but in this article, we are most interested in SMD LEDs, their testing, application and difference between them and COB LEDs.

What is a SMD LED?

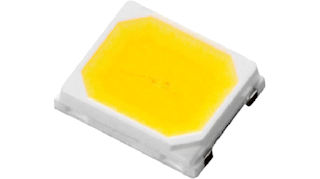

Surface-Mount Device, Light-Emitting Diode, or SMD LED, is a category of LED that is distinguished by having a 3 in 1 encapsulation, or integrating all three colours (Red, Green, and Blue) in a single system. SMD LEDs are currently the most used type of LED on the market. The large-scale production of manufacturers has made it the cheapest kind of LED available in the market at the moment.

SMD LED structure and design

SMD LEDs are made up of three cells and have a rectangular shape. These cells contain a semiconductor crystal that glows when current passes through it, making it a luminescent component.

buy smd led which have a specific number of contacts for welding depending on the number of cells it contains. One of them is always the anode (+) and the other will be the cathode for a single-color LED (-). An SMD RGB LED typically has an anode and a cathode contact for each luminescent component. Both the configuration and the number of connection points can differ depending on the manufacturer and the LED specification.

Resins are used to completely cover the upper part and protect the SMD cells. These SMD resins come in a variety of hues and tones.

Assembly

The front of the LED module is polarised before being assembled on the circuit board. To prevent future issues like loose or dysfunctional LEDs, it is crucial that this procedure be performed using high-quality equipment.

SMD LED sizes

LED types are categorised according to their size using a 4-digit number, with the first two digits representing the length and the following two representing the height of the LED in tenths of a millimetre. A 5050 led, for instance, measures 5x5mm. The most popular SMD LED types are displayed in the following table:

How to test SMD LEDs with a multimeter?

Before you begin a project, it's a good idea to test the electrical characteristics of the LEDs. This can be accomplished by using a multimeter to measure the led's resistance, forward voltage, and maximum current draw when it is included in a circuit.

Perform the following actions when using a multimeter to test an SMD led:

⦁ A multimeter, an SMD LED, a solderless breadboard, wires, a soldering iron, and solder are the items you will need to have ready.

⦁ With the multimeter set to 20 volts, start by gauging the voltage between the negative and positive.

⦁ Then, connect your SMD led to a resistor by inserting it into the solderless breadboard.

⦁ Then join a wire to your multimeter's positive terminal and a different wire to its negative terminal, and finally join the other end of the wires to the resistor.

⦁ Turn the multimeter to 20 volts and then touch the positive and negative ends of each wire to the multimeter.

⦁ If the diode is luminating then everything is alright otherwise change the LED.

Following things to be kept in mind while testing the LED:

⦁ One of the main things is the fact that you need to find the right pins on the multimeter in order to test the SMD LED.

⦁ If you don’t find the right pins, you might damage the SMD LED.

⦁ When it comes to testing SMD LEDs, there is a need for a low voltage DC power supply. Ideally, you want a power supply that is of a high quality and has a low dropout voltage.

⦁ It is also essential to have a power supply that is not capable of producing a high voltage, which can damage the LED.

What are the applications of SMD LED?

SMD LEDs, as you may already be aware, are the most widely used types of LEDs and are found in a variety of consumer and industrial goods such as:

⦁ Domestic and industrial lighting systems

⦁ Automobile lighting

⦁ Personal electronic devices such as LED screens, televisions, projectors

⦁ Decorative lighting

⦁ Camera flashes and automotive heat lamps

⦁ Digital computers and calculators.

⦁ Microprocessors and multiplexers

⦁ Traffic signals and Burglar alarms systems.

And so on.

What is the difference between COB Lighting and SMD LEDs?

SMD (Surface-mounted devices) is a led chip mounted on the surface of a PCB (printed circuit board). They are produced using surface mount technology (SMT).

COB (Chip on board) is an LED chip in direct contact with a substrate such as silicon carbide or sapphire. The chips are closely packed next to each other. COB has multiple diodes, with a minimum of 9, on the printed circuit board, 1 circuit, and two contacts.

To differentiate between two, refer to the comparison table given below:

Advantages of using SMD LED:

SMD LEDs are one of the most common types of lighting that we have today. They are used in many outdoor applications to provide adequate lighting and are also energy efficient. That said, here are other benefits of these lights;

⦁ They come in different shapes, and designs

One of the main advantages of these lights is that they come in different designs, shapes, and sizes. They have intricate designs, such as the SMD 2835, SMD 3030. SMD 3014, SMD 5050, with a width of 3.5mm, 3.0mm, 2.8mm, and 5 mm, respectively.

As mentioned above, the chips used to make these lights are tiny and built on a flat rectangular-shaped object. Their small size makes them more adaptable and ideal for retrofitting.

⦁ They have a larger beam angle

SMD LEDs don’t rely on an epoxy covering to focus their light. As a result, they offer a larger beam angle compared to ordinary LEDs. Its beam angle is around 110 degrees in the horizontal and more than 120 degrees viewing angle in the vertical direction.

⦁ They have a good light distribution and mixing

SMD can produce different light color outputs at different beam angles, including red, blue, and green. When adjusted to different angles, they produce multiple color effects.

The output of these lights is about 50-100 lumens per watt which makes them produce bright light.

⦁ Easy to install

The design of the aluminum alloy material box’s structure is incredibly light. Due to their architectural structure, the SMD lights are small and very easy to install.

Advantages of using COB Lighting:

COB LED lights are used in numerous applications, including street lighting, playground lighting, light strip, downlights, and high bay lighting, to mention a few. So why do people use this type of LED lighting? Read on.

⦁ Better lighting effect

COB lights have a better lighting effect and produce a bright, high-quality light. Due to its chip design, it can incorporate more LED chips resulting in glare-free uniform lighting.

⦁ Better heat efficiency and lumen per watt ratio

COB lights have an improved lumen per watt ratio and better heat efficiency due to their design. They produce more lumens of above 80 using less energy.

⦁ Better heat distribution

COB LEDs have a small number of components and a large cooling area. The thermal sink on the COB is aimed at the circuit board. Also, the substrate material, board circuit, and heat sink components are responsible for the COB LED’s heat dispersion efficiency.

Comments

Post a Comment